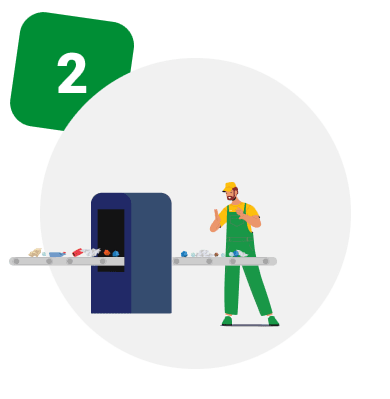

Households collect around 50%-60% of this using a PMD (Plastic, Metal, Drinks Cartons) bag (source). How often these bags are collected varies from municipality to municipality. The bags then go to a sorting centre to separate the various materials, including packaging films. Many films have been used for food packaging, so they are often contaminated with residues that require cleaning.

It makes sense to reuse or recycle commonly used materials, which helps to reduce the amount of waste and ensures less plastic ends up in the environment. It also means we need to burn less plastic and fewer emissions occur. Recycling helps to reduce the amount of greenhouse gas emissions, which in turn reduces the impact on the environment.